Coffee processing - Natural

Discover our classics

-

La Fiesta - Espresso

from €13,90

from €13,90€39,71 / kg

-

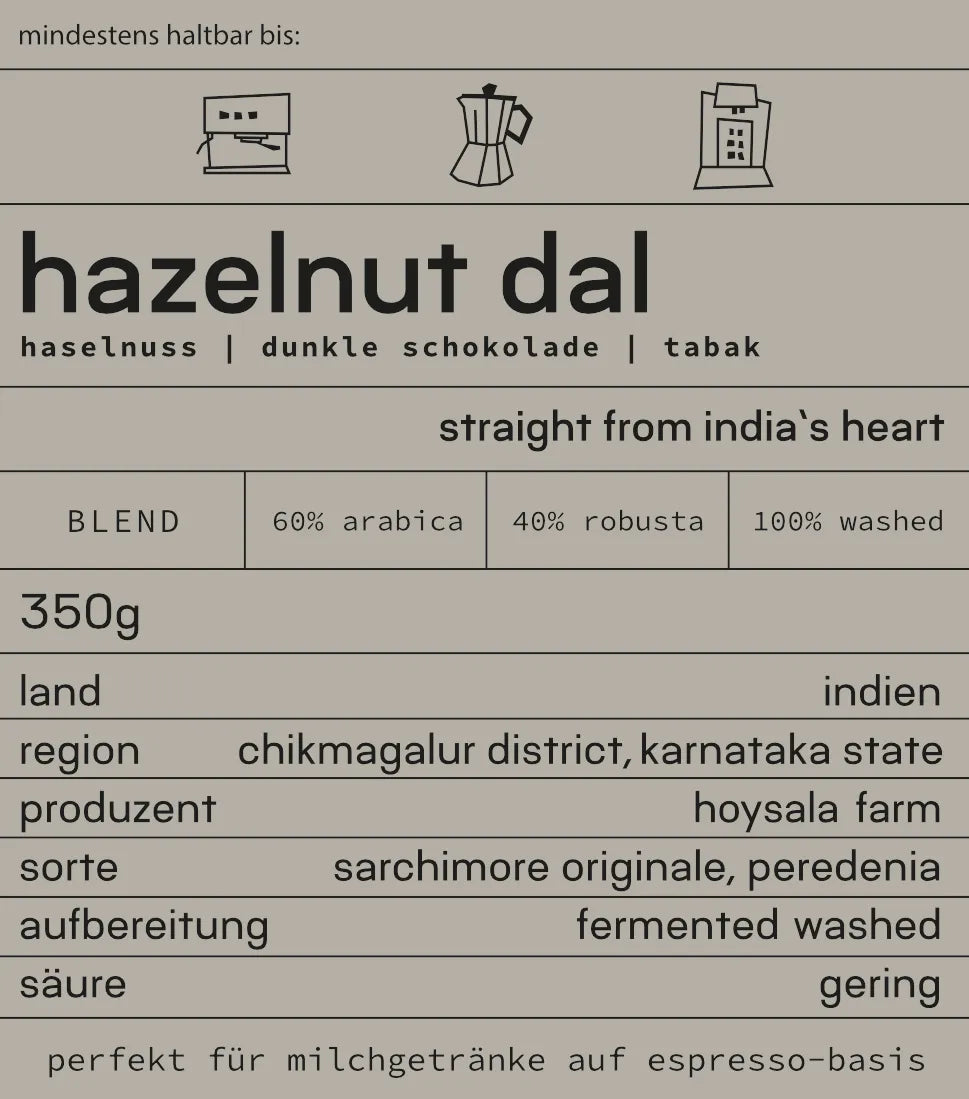

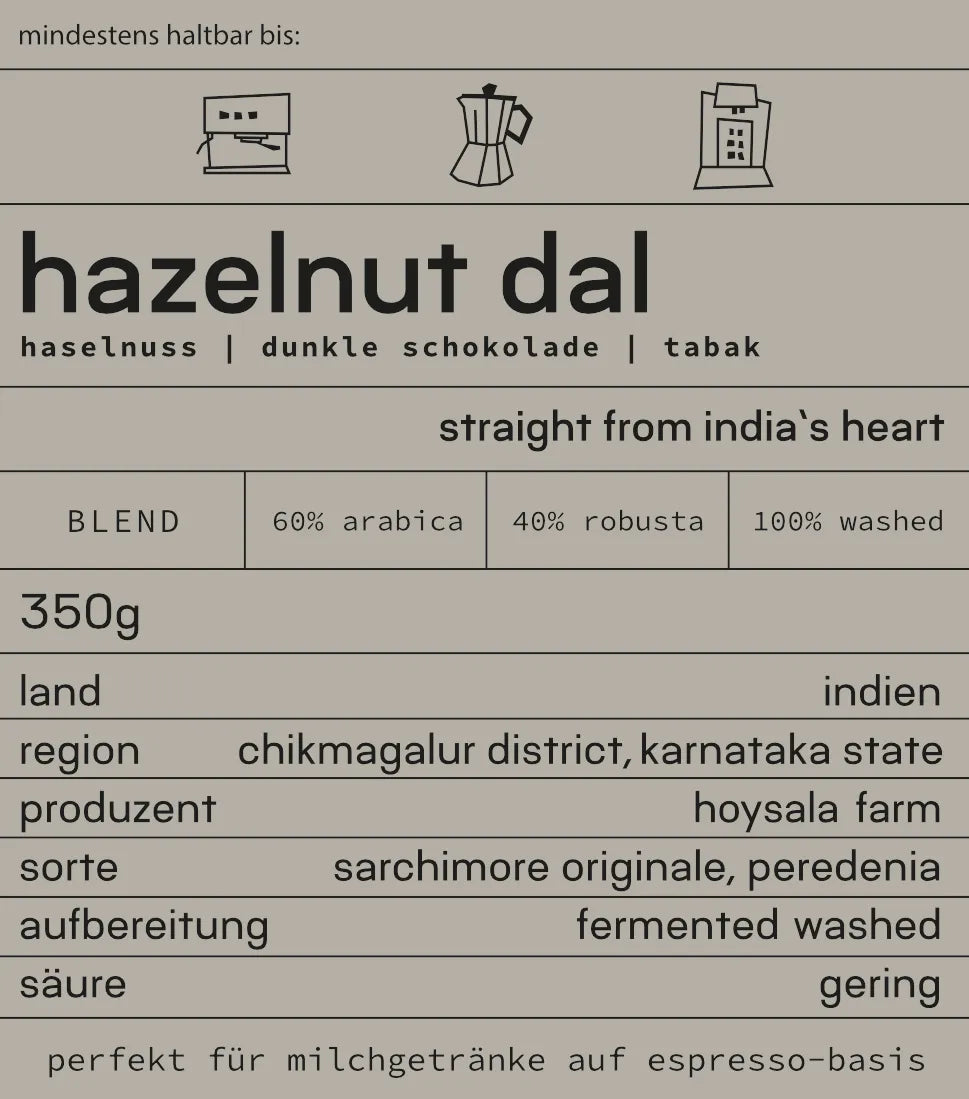

Hazelnut Dal - Espresso

from €14,90

from €14,90€42,57 / kg

-

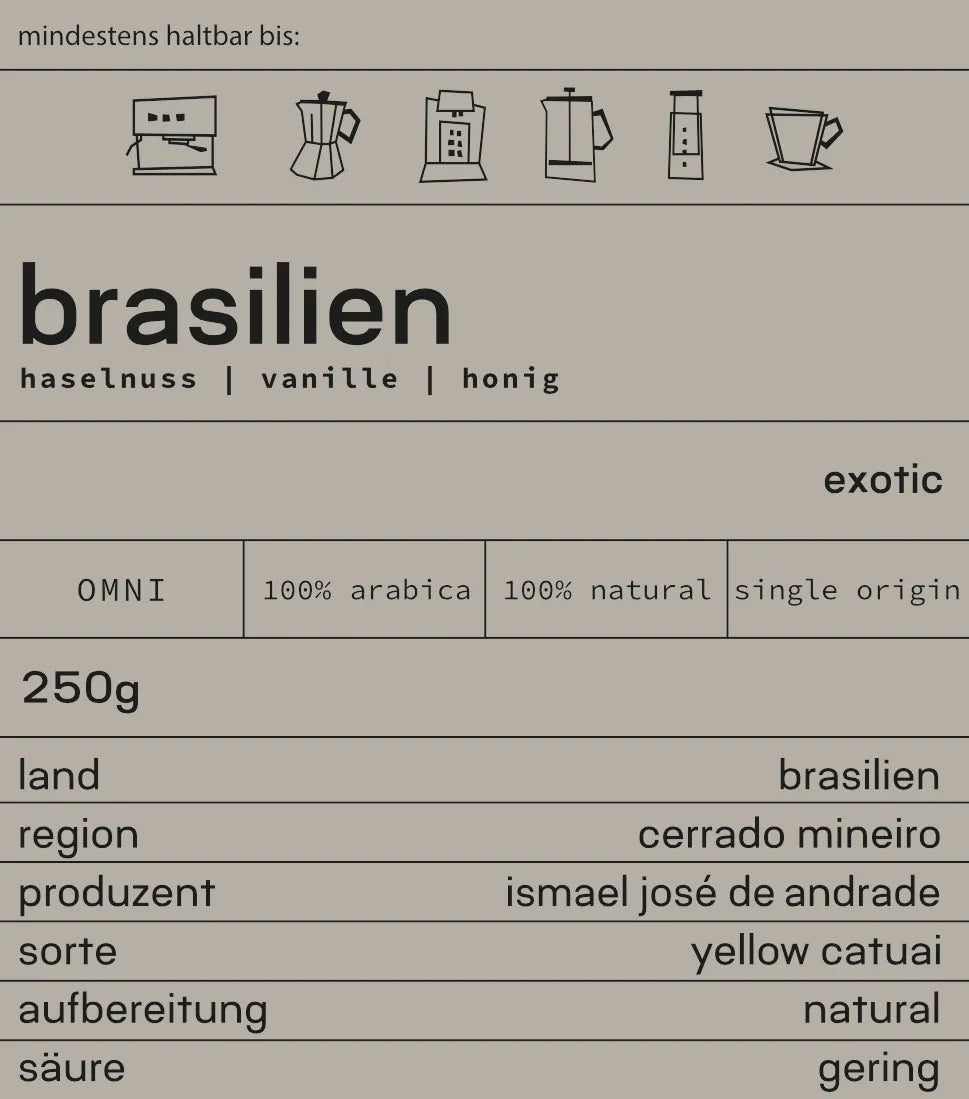

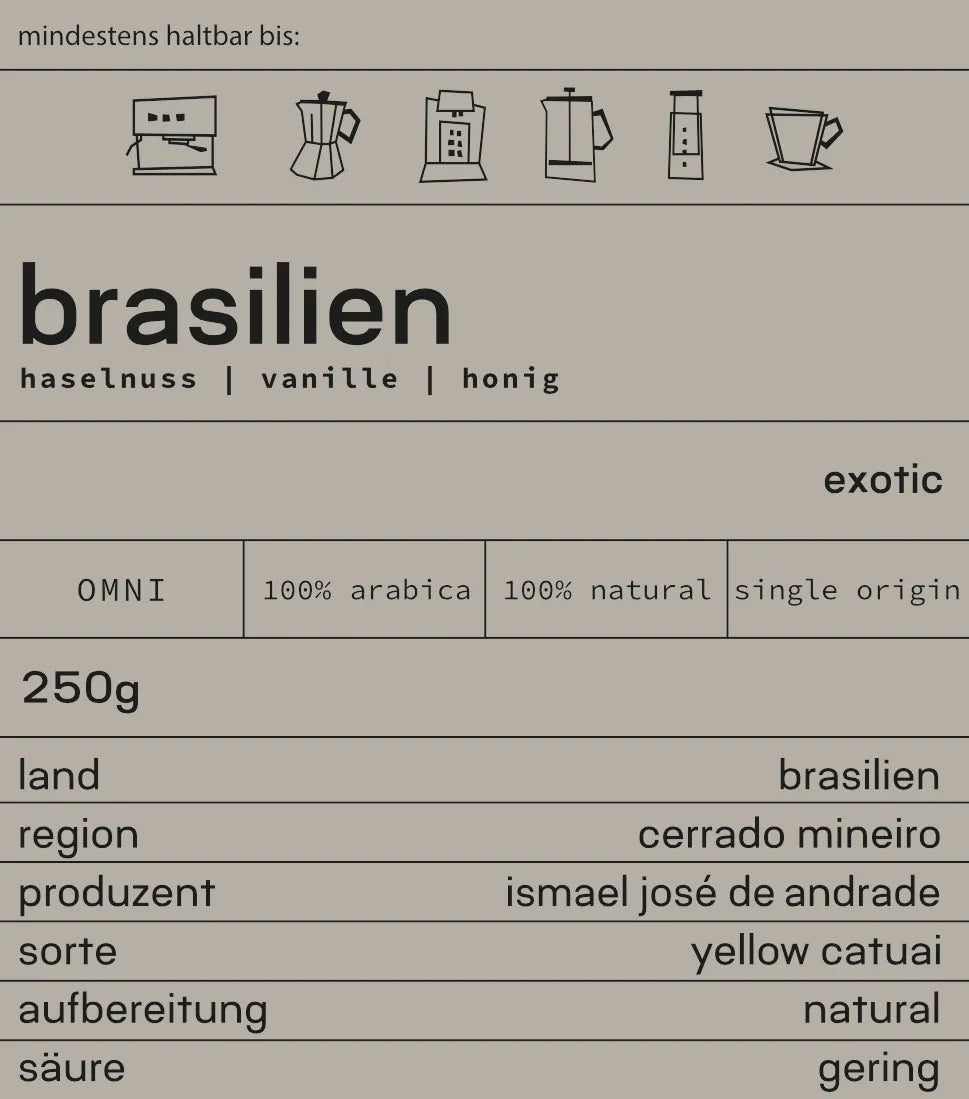

Brazil Exotic - Omni Roast

from €9,90

from €9,90€39,60 / kg